We get it – 3D printing, of course, is better than 2D printing. It’s a no-brainer, all right. However, not many technology enthusiasts actually understand why 3D printers are better placed to transform the way humans change digital content to tangible content than 2D printers.

The word “printer” is generally understood to mean the device that uses ink or laser to print text or visual content on paper. Even today, most home desktops are connected to a printer to manage routine printing tasks. In offices, printers are as ubiquitous as information! Today, we have all-in-one devices that perform the functions of printers, scanners, fax machines, and copiers, and these are so inexpensive that home desktop owners can also easily afford them.

Too bad they sometimes do not work with certain laptops and with some routers, which is a total pain, but that is another topic.

However, 2D printers took almost three decades to be available in compact size and at the right price. Why 3D printers are better placed is because we won’t have to wait for another three decades for them to be in our homes and offices.

So, while 3D printing might appear as 2D printing with another dimension, the technological lifecycle and evolution it’s going through is entirely different from what we observed for 2D printers. And that’s where all the advantages are. In this guide, we will explore them.

Internet — easing adoption of 3D printers

“Desktop publishing” was not a reality until the time 2D printers became affordable enough for home use. However, 3D printers will not have to wait for long, because the Internet empowers the creation of models where anyone can take the services of 3D printing by sharing their prototype files with someone who owns it, and just pay for the use. Business models that use the Internet as the channel of distribution will make 3D printers accessible for enterprise users as well as hobbyists. Also, such business models will also promote 3D printer sales.

3D printers as drivers of product innovation

Design and materials consulting for 3D printing is set to be big because additive manufacturing (that’s the actual technical term for what we call 3D printing) is slated to grow by 400 percent by 2019, as compared to its state in 2014.

Many service centers already offer these consulting services, making it easier for potential users to experience and benefit from 3D printing technology. This opens up the gates for innovative small-scale product development and prototyping. This potentially makes 3D printers the tools for unparalleled growth in product design in the years to come.

Design and prototyping capabilities coming to mobile devices

Not long back, CAD designs were the domain of expert designers only. Today, however, we’re moving toward times when mobile apps will be able to easily scan and render high-quality CAD drawings for 3D printing. These apps will also assist users in designing and creating innovative CAD prototypes. With time, the ease of use will improve. This means that 3D printers will be a part of the tech hobbyist and professional’s life much sooner than it seems today.

That is awesome since when you think about 3D watching a movie, the technology is not that special and it bothers your brain, which undermines your enjoyment. This makes many people still want to stick with 2D televisions, which is what they do and it certainly helps make this decision easier when 3D is more expensive. Not even an amazing movie like “American Assassin” or “Transformers” is that tremendous in 3D when it is hard to grasp what is going on!

But when it comes to printing, 3D has substantial advantages over 2D.

Lowering costs and market expansion

Make no mistake — 3D printers cost a lot, and it might be preposterous to even suggest that they are affordable enough to be categorized as a consumer-electronics product. However, their costs are dipping. The key factors that have helped manufacturers bring down costs are:

- Lowering raw materials cost.

- Exports resulting in larger orders, enabling manufacturers to build economies of scale.

- Competition from startups looking to capture the market on price points.

- Technological advancements.

- Constant innovation and improvement in 3D printer designs.

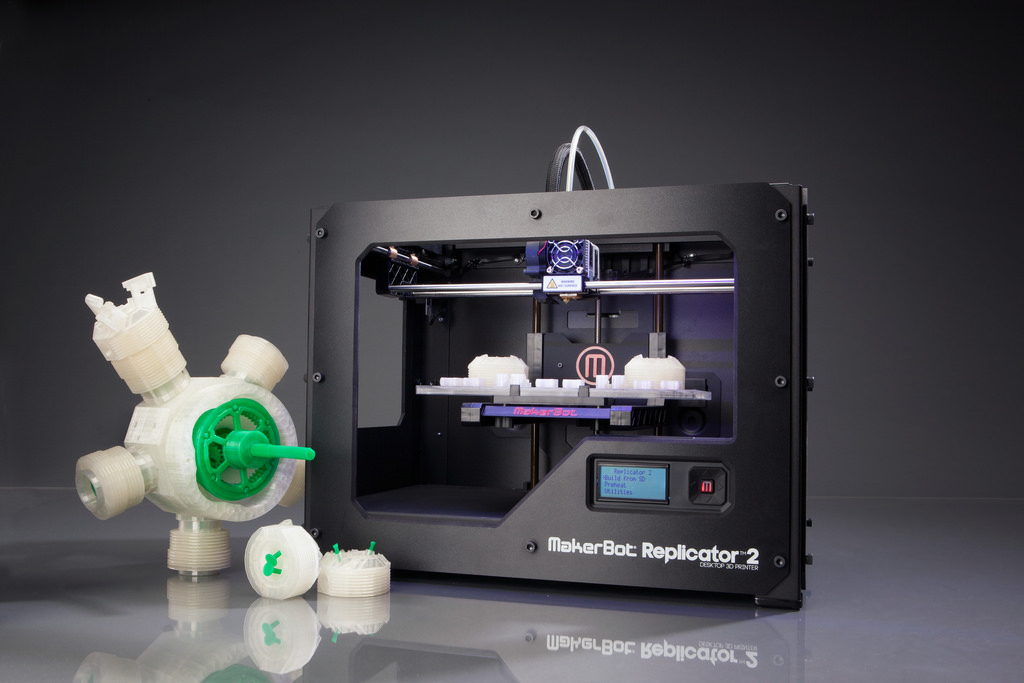

Right until 2015, Stratasys and 3D Systems were the two giants of the 3D printers market, accounting for more than 55 percent of the market share. However, by the end of 2015, there were already 100 suppliers. New manufacturers are jumping into the ecosystem every month, and this augers well for the future of 3D printing technology availability for small businesses and home users.

3D printing applications

The applications of 3D printers are fascinating, to say the least. In 2014, BAE Systems revealed that British fighter jets had flown with 3D printed components in them. And here are some of the most mindboggling examples of 3D printing is already changing the landscape.

- Custom fit casts and holders that repair fractures much quicker than standard-sized casts.

- Prosthetic limbs, for instance, made by Cyborg Beast, which can be downloaded for free, and then printed for about $50 for the cost of parts!

- Hollow shells of organs, by laying down structures of protein scaffoldings (called collagen) that hold cells together. Doctors can fill these shells with stem cells to make living tissue for transplants.

Shocked about organ printing? What about printed meat burgers? The technique described above can be used to 3D print steaks and bacon using collagen, and seeding them with stem cells. A startup called Modern Meadow is trying to advance this technique beyond a concept, and into a reality.

Imagine a situation where you need an all-important air conditioner part to make your home AC work. You go to the maker’s website, download a CAD file of the part, and print it on your home 3D printer, and complete the AC repair within minutes (that beats waiting for UPS or Fed Ex, for sure!). That’s the power, prowess, and potential of 3D printing technology, which is way beyond the scale and impact of 2D printers.

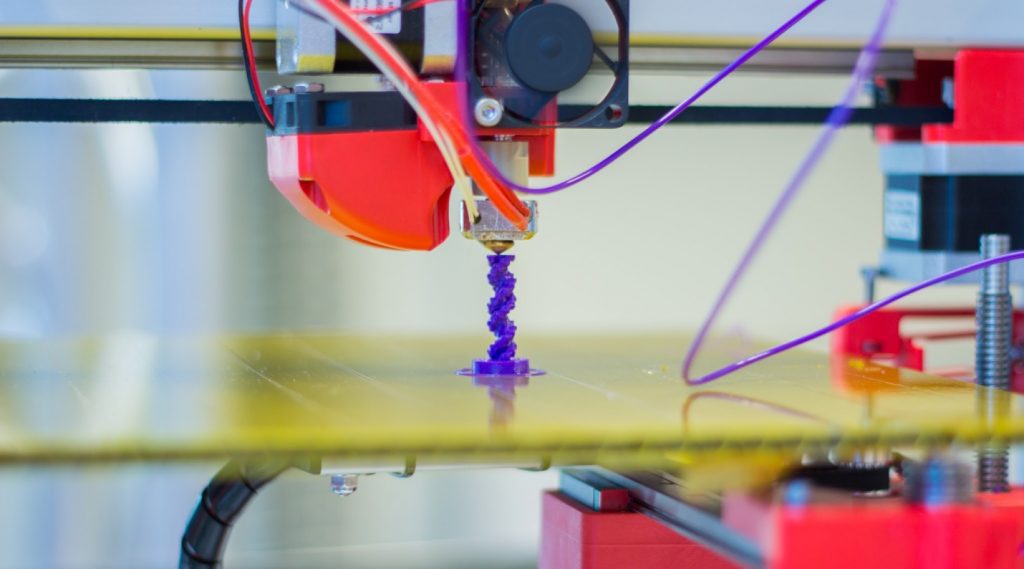

3D printing is basically microscale manufacturing

Comparing 2D printers and 3D printers is, in some ways, not even justified, because what we’ve actually got with 3D printing is actual microscale manufacturing. 3D printers take plastic-based raw material and add layer after layer of the material to create “things.” We mentioned it earlier — it’s actually additive manufacturing, and not exactly printing. But the name has stuck, and nobody’s complaining.

3D printing technology has been maturing at a superb pace in the past few years. The times when you will not have to think twice before bringing home a latest 3D printer are not too far away. Which aisle in Best Buy will they soon be in?

Photo credit: Wikimedia